Project : Effluent Treatment Plant Installation

Client : Manimed PharmaCeutical

Plant Location : Ahmedabad, Gujarat.

Design Concept :

| Plant Capacity……………………. | 2 M3/hr |

| Flow Rate…………………………… | 0.334 M3/hr |

| Service Cycle………………………. | 6 hrs |

|

Plant Capacity |

|

Inlet Parameter of Effluent Waste Water :

| Sr. No. | Parameter | Unit | Averages |

| 1. | pH…………………………….. | -………………………………… | 6-8 |

| 2. | TDS……………………………. | ppm…………………………… | 1200-2000 |

| 3. | TSS…………………………….. | ppm…………………………… | 200-400 |

| 4. | Color………………………….. | ppm…………………………… | 40-100 |

| 5. | BOD…………………………… | ppm…………………………… | 190-300 |

| 6. | COD…………………………… | ppm…………………………… | 450-5000 |

| 7. | Oil & Grease………………. | ppm…………………………… | 2 |

| 8. | Sulphate…………………….. | ppm…………………………… | 99-200 |

| 9. | Chloride……………………… | ppm…………………………… | 400-600 |

| 10. | Ammonical Nitrogen….. | ppm…………………………… | 39-100 |

| 11. | Sodium……………………… | ppm…………………………… | 520-600 |

|

Inlet Effluent Parameter |

|||

Outlet Parameter of Treated Effluent :

| Sr. No. | Parameter | Unit | Averages |

| 1. | pH…………………………….. | -………………………………… | 6.5 to 7.8 |

| 2. | TDS……………………………. | ppm…………………………… | 1200 |

| 3. | TSS…………………………….. | ppm…………………………… | 100 |

| 4. | Color………………………….. | ppm…………………………… | 100 |

| 5. | BOD…………………………… | ppm…………………………… | 30 |

| 6. | COD…………………………… | ppm…………………………… | 100 |

| 7. | Oil & Grease………………. | ppm…………………………… | 2 |

| 8. | Sulphate…………………….. | ppm…………………………… | 1000 |

| 9. | Chloride……………………… | ppm…………………………… | 600 |

| 10. | Ammonical Nitrogen….. | ppm…………………………… | 50 |

| 11. | Sodium……………………… | ppm…………………………… | 520 |

|

Outlet Effluent Parameter |

|||

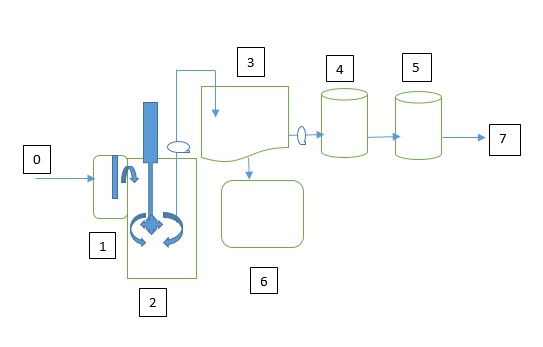

Effluent Treatment Process :

| Sr No. | ETP Process Unit | Size(LxBxH) in M | Capacity (Liter) |

| 0 | Effluent Inlet | – | – |

| 1 | Oil & Grease Chamber | 0.5 x 0.5 x 1 | 500 |

| 2 | Collection cum neutralization tank | 2 x 1.5 x 2 | 6000 |

| 3 | Settling Tank | 2 x 2x 2 | 8000 |

| 4 | Sludge Drying Bed | 1.2 x 1.2 x 2 | 2880 |

| 5 | Pressure Sand Filter | 0.2 x 1.2 | 100 |

| 6 | Activated Carbon Filter | 0.2 x 1.2 | 100 |

| 7 | Water Supply for Gardening Propose | – | – |

| 8 | Water Evaporation System | 500 Liter/Day | 500 Liter/Day |

|

ETP Process Unit Detail |

|||

Effluent Treatment Process Description :

| Sr.No. | Process Unit | Process Description |

| 1. | Oil & Grease Chamber | Washing water from Tablet, Ointment unit transfer to Oil & Grease Tank to trap the Oil Content. Oil and water will be separate through density difference. Water having more density forms the lower layer and oil having less density forms the upper layer. |

| 2. | Collection cum Neutralization Tank | Effluent from oil & grease tank transfer to collection cum neutralization tank by gravity base. Initially pH of effluent water set up at 8.5 by chemical dosing of direct flocculants. Sub sequently pH raise to 10.5-11.5 by lime dosing. Chemical mixing is done by Agitator having 1 HP Gear Motor & SS Impeller Shaft. Initially chemical dosing will help to maximum sludge separation.

Coagulation-Flocculation Separation : The use chemical re-agent to destabilize and increase the size of the particles ; mixing; increasing of flog size pH of effluent will be maintain at 7.8 settled for 3 hrs then supernant transfer to settling tank and residual sludge transfer to sludge drying bed through 1 HP mud pump. |

| 3. | Settling Tank | Treated effluent from collection cum neutralization tank transfer to settling tank by water transfer pump. Flocculated water will be settled to remove the turbidity of water. |

| 4. | Pressure Sand Filter | Settled water will be treasnfer to pressure sand filter by water transfer pump. Pressure sand filter remove suspened solids. |

| 5. | Activated Carbon Filter | Filtered water from pressure sand filter will be filter out in activated carbon filter to remove the chlorine content and residual. |

| 6. | Water supply for gardening | Filter out water of carbon filter utilize for gardening purpose |

| 7. | Evaporation System | If area is not enough to avaible for gardening then water will be evaporate in Water Evaporator. |

|

ETP Process Description |

||

Technical Specification :

| Oil & Grease Chamber | ||

| 1 | Quantity | 1 Nos |

| 2 | Type | Manual Batch- Density Difference |

| 3 | Size | 500 Liter |

| 4 | MOC | Civil Work- 225mm Brick Plaster |

| Collection Cum Neutralization Tank | ||

| 1 | Quantity | 1 Nos |

| 2 | Capacity | 6000 Liter |

| 3 | Design | As per drawing |

| 4 | MOC | Civil Work-225mm Brick Plaster |

| Alum Dosing System | ||

| 1 | Dosing Tank capacity | 100 Liter |

| 2 | MOC | HDPE |

| 3 | Operation | Manual Valve Type |

| 4 | Chemical | Alum |

| 5 | Make | Suntex |

| Poly Electrolyte Dosing System | ||

| 1 | Dosing Tank Capacity | 100 Liter |

| 2 | MOC | HDPE |

| 3 | Operation | Manual Valve Type |

| 4 | Chemical | Anion/Cation Polyelectorlyte |

| 5 | Make | Suntex |

| pH Maintenance Dosing System | ||

| 1 | Dosing Tank Capacity | 100 Liter |

| 2 | MOC | HDPE |

| 3 | Operation | Manual Valve Type |

| 4 | Chemical | HCL / NaOH |

| 5 | Make | Suntex |

| Settling Tank | ||

| 1 | Quantity | 1 Nos |

| 2 | Capacity | 8000 Liter |

| 3 | Design | AS per drawing |

| 4 | MOC | Civil Work- 225mm brick plaster |

| Pressure Sand Filter | ||

| 1 | Quantity | 1 Nos |

| 2 | Capacity | 0.5 m3/hr |

| 3 | Design Data | Min. & Max. Press. (2.4 -3.5 kg/cm2) |

| 4 | MOC | FRP |

| 5 | Make | Pentair |

| 6 | Mode of Operation | Manual Multiport Valve |

| 7 | Media Type | Filtration graded sand & pebbles |

| 8 | Design Velocity | 6 M/hr |

| Activated Carbon Filter | ||

| 1 | Quantity | 1 Nos |

| 2 | Capacity | 0.5 m3/hr |

| 3 | Design Data | Min. & Max. Press. (2.4 -3.5 kg/cm2) |

| 4 | MOC | FRP |

| 5 | Make | Pentair |

| 6 | Mode of Operation | Manual Multiport Valve |

| 7 | Media Type | Filtration graded sand & pebbles |

| 8 | Design Velocity | 6 M/hr |

| Sludge Drying Bed | ||

| 1 | Quantity | 1 Nos |

| 2 | Capacity | 2880 Liter |

| 3 | Design | AS per drawing |

| 4 | MOC | Civil Work- 225mm brick plaster |

| Water Evaporation System | ||

| 1 | Evaporator Type | Electric Heated |

| 2 | Evaporator | 500 Litres/day |

| 3 | Size | 2 Ft [Dia.] x 2.75 Ft [ Height] |

| 4 | MOC | MS IS 2062 |

| 5 | Thickness | 6 MM Flat Bottom |

| 6 | Heating Media | Electric |

| 7 | Quantity of Heater | 3 Nos. |

| 8 | Heater Capacity | 3 KW Each |

| 9 | Total load of heaters | 9 KW |

| 10 | Insulation | With outer side insulation 40 mm with glass wool and coated by 26 gauge aluminium sheet with other required connection inlet and outlet |

| 11 | Electric. | |

| Dial Type Thermocouple “J” Type | ||

| Contactor – Schneider Make | ||

| MCB-Schneider Make | ||

| Liquid level controller – shut off heater when water level low | ||

| RYB Light | ||

| On/OFF Push Button – L&T Make | ||

| Interconnecting Piping & Valves | ||

| 1 | Quantity Offered | One Lot. |

| 2 | Type | UPVC /HDPE/GI As applicable Complete Interconnecting Piping Within The Battery Limits |

| 3 | Valves | Ball Valve and manual valves as required |

| 4 | Supports | Pipe Supports for interconnecting piping |

| Instrumentation | ||

| 1 | Pressure Gauges | At Feed of carbon filter & pressure sand filter |

| 2 | Flow meter | Discharge of Activated Carbon Filter & Pressure Sand Filter |

| 3 | Energy Meter | HPL Make; Analoge Type KWH Meter 3Ph Four Wire 10-60 Amps |

|

Technical Specification |

||

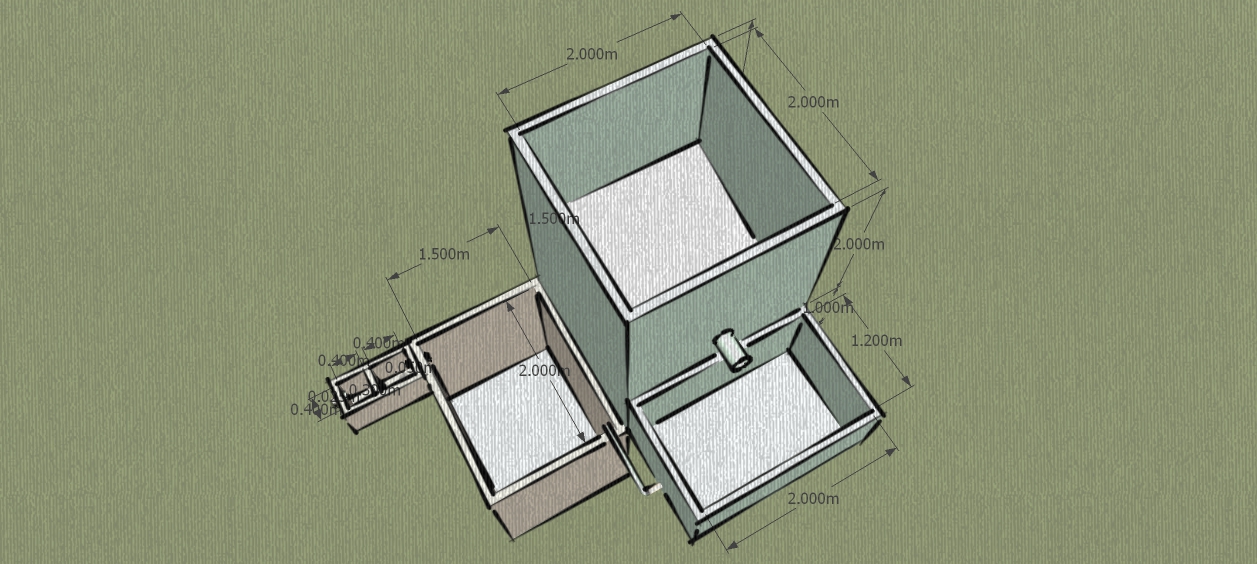

Civil Work Specification :

| Sr. No. | ETP Process Unit | Size [ L x B X H ] | Capacity [ Liter] | Civil Work Type | Work Scope |

| 1 | Oil & Grease Chamber | [ 0.5 x 0.5 x 1] M | 500 | 250 mm brick work | Client |

| 2 | Collection Cum Neutralization Tank | [ 2 x 1.5 x 2 ] M | 6000 | 250 mm brick work | Client |

| 3 | Settling Tank | [ 2 x 2 x 2] M | 8000 | 250 mm brick work | Client |

| 4 | Sludge Drying Bed | [ 1.2 x 1.2 x 2] M | 2880 | 250 mm brick work | Client |

|

Civil Work Specification |

|||||

Installed Plant Process Unit Layout :

| Sr No. | ETP Process Unit | Size(LxBxH) in M | Capacity (Liter) |

| 0 | Effluent Inlet | – | – |

| 1 | Oil & Grease Chamber | 0.5 x 0.5 x 1 | 500 |

| 2 | Collection cum neutralization tank | 2 x 1.5 x 2 | 6000 |

| 3 | Settling Tank | 2 x 2x 2 | 8000 |

| 4 | Sludge Drying Bed | 1.2 x 1.2 x 1 | 2880 |

| 5 | Pressure Sand Filter | 0.2 x 1.2 | 100 |

| 6 | Activated Carbon Filter | 0.2 x 1.2 | 100 |

| 7 | Water Supply for Gardening Propose | – | – |

| 8 | Alum Dosing System | – | 100 |

| 9 | Poly Electrolyte Dosing System | – | 100 |

| 10 | pH Control System | – | 100 |

| 11 | Water Evaporation System | – | 500 |

|

ETP Process Unit Detail |

|||

Installation Qualification :

| Sr. No. | Item Name | Specification | Checked By | Status |

| Oil & Grease Chamber | ||||

| 1 | Quantity | 1 Nos | MTPL | Ok |

| 2 | Type | Manual Batch- Density Difference | MTPL | Ok |

| 3 | Size | 500 Liter | MTPL | Ok |

| 4 | MOC | Civil Work- 225mm Brick Plaster | MTPL | Ok |

| Collection Cum Neutralization Tank | ||||

| 1 | Quantity | 1 Nos | MTPL | Ok |

| 2 | Capacity | 6000 Liter | MTPL | Ok |

| 3 | Design | As per drawing | MTPL | Ok |

| 4 | MOC | Civil Work-225mm Brick Plaster | MTPL | Ok |

| Alum Dosing System | ||||

| 1 | Dosing Tank capacity | 100 Liter | MTPL | Ok |

| 2 | MOC | HDPE | MTPL | Ok |

| 3 | Operation | Manual Valve Type | MTPL | Ok |

| 4 | Chemical | Alum | MTPL | Ok |

| 5 | Make | Suntex | MTPL | Ok |

| Poly Electrolyte Dosing System | ||||

| 1 | Dosing Tank Capacity | 100 Liter | MTPL | Ok |

| 2 | MOC | HDPE | MTPL | Ok |

| 3 | Operation | Manual Valve Type | MTPL | Ok |

| 4 | Chemical | Anion/Cation Polyelectorlyte | MTPL | Ok |

| 5 | Make | Suntex | MTPL | Ok |

| pH Maintenance Dosing System | ||||

| 1 | Dosing Tank Capacity | 100 Liter | MTPL | Ok |

| 2 | MOC | HDPE | MTPL | Ok |

| 3 | Operation | Manual Valve Type | MTPL | Ok |

| 4 | Chemical | HCL / NaOH | MTPL | Ok |

| 5 | Make | Suntex | MTPL | Ok |

| Settling Tank | ||||

| 1 | Quantity | 1 Nos | MTPL | Ok |

| 2 | Capacity | 8000 Liter | MTPL | Ok |

| 3 | Design | AS per drawing | MTPL | Ok |

| 4 | MOC | Civil Work- 225mm brick plaster | MTPL | Ok |

| Pressure Sand Filter | ||||

| 1 | Quantity | 1 Nos | MTPL | Ok |

| 2 | Capacity | 0.5 m3/hr | MTPL | Ok |

| 3 | Design Data | Min. & Max. Press. (2.4 -3.5 kg/cm2) | MTPL | Ok |

| 4 | MOC | FRP | MTPL | Ok |

| 5 | Make | Pentair | MTPL | Ok |

| 6 | Mode of Operation | Manual Multiport Valve | MTPL | Ok |

| 7 | Media Type | Filtration graded sand & pebbles | MTPL | Ok |

| 8 | Design Velocity | 6 M/hr | MTPL | Ok |

| Activated Carbon Filter | ||||

| 1 | Quantity | 1 Nos | MTPL | Ok |

| 2 | Capacity | 0.5 m3/hr | MTPL | Ok |

| 3 | Design Data | Min. & Max. Press. (2.4 -3.5 kg/cm2) | MTPL | Ok |

| 4 | MOC | FRP | MTPL | Ok |

| 5 | Make | Pentair | MTPL | Ok |

| 6 | Mode of Operation | Manual Multiport Valve | MTPL | Ok |

| 7 | Media Type | Filtration graded sand & pebbles | MTPL | Ok |

| 8 | Design Velocity | 6 M/hr | MTPL | Ok |

| Sludge Drying Bed | ||||

| 1 | Quantity | 1 Nos | MTPL | Ok |

| 2 | Capacity | 2400 Liter | MTPL | Ok |

| 3 | Design | AS per drawing | MTPL | Ok |

| 4 | MOC | Civil Work- 225mm brick plaster | MTPL | Ok |

| Water Evaporation System | ||||

| 1 | Evaporator Type | Electric Heated | MTPL | Ok |

| 2 | Evaporator | 500 Litres/day | MTPL | Ok |

| 3 | Size | 2 Ft [Dia.] x 2.75 Ft [ Height] | MTPL | Ok |

| 4 | MOC | MS IS 2062 | MTPL | Ok |

| 5 | Thickness | 6 MM Flat Bottom | MTPL | Ok |

| 6 | Heating Media | Electric | MTPL | Ok |

| 7 | Quantity of Heater | 3 Nos. | MTPL | Ok |

| 8 | Heater Capacity | 3 KW Each | MTPL | Ok |

| 9 | Total load of heaters | 9 KW | MTPL | Ok |

| 10 | Insulation | With outer side insulation 40 mm with glass wool and coated by 26 gauge aluminium sheet with other required connection inlet and outlet | MTPL | Ok |

| 11 | Electric. | MTPL | Ok | |

| Dial Type Thermocouple “J” Type | ||||

| Contactor – Schneider Make | ||||

| MCB-Schneider Make | ||||

| Liquid level controller – shut off heater when water level low | ||||

| RYB Light | ||||

| On/OFF Push Button – L&T Make | ||||

| Interconnecting Piping & Valves | ||||

| 1 | Quantity Offered | One Lot. | MTPL | Ok |

| 2 | Type | UPVC /HDPE/GI As applicable Complete Interconnecting Piping Within The Battery Limits | MTPL | Ok |

| 3 | Valves | Ball Valve and manual valves as required | MTPL | Ok |

| 4 | Supports | Pipe Supports for interconnecting piping | MTPL | Ok |

| Instrumentation | ||||

| 1 | Pressure Gauges | At Feed of carbon filter & pressure sand filter | MTPL | Ok |

| 2 | Flow meter | Discharge of Activated Carbon Filter & Pressure Sand Filter; | MTPL | Ok |

| 3 | Energy Meter | HPL Make; Analoge Type KWH Meter 3Ph Four Wire 10-60 Amps | MTPL | Ok |

|

Installation Qualification |

||||

Operation specification :

| Sr. No. | ETP Process Unit Segment | Action Required | Frequency |

| 1 | Energy Meter | To note down energy meter reading in ETP Manual before starting the electricity in ETP Plant | Daily |

| 2 | Water Flow Meter | To note down the energy meter reading of activated carbon discharge point and water evaporation inlet unit | Daily |

| 3 | pH Check | To Check the pH of effluent Inlet | Daily |

| 4 | ETP Inlet Point | To Check the flow of effluent from process unit to ETP is proper | Weekly |

| To remove the plastic and other non- treatable waste from inlet | Weekly | ||

| 5 | Oil & Grease Unit | To check the whether Oil is collect in first part of unit or not. | Daily |

| To collect the excessive oil from past of oil & grease unit through manual operation | Weekly | ||

| If there is excessive emulsion type sludge then manually required to extract and dry in sludge drying bed. | Weekly | ||

| 6 | Collection cum Neutralization Tank | To Take the dosing operation of Non- ferric Alum as per given SOP Calculation | Daily |

| To Start the Agitator for mixing propose | Daily | ||

| To Take the dosing operation of Poly Electrolyte as per SOP Calculation | Daily | ||

| To Maintain the pH@7.0 by dosing of pH Control | Daily | ||

| To check the chemical mixing performance through natural circulation by visual observation. | Daily | ||

| If mixing is not proper than ETP Operator will require to recirculation of water through Water Pump | Daily | ||

| If there is excessive sludge found in tank then manual operation for sludge removal required | Monthly | ||

| 7 | Alum Dosing Dosing Tank | To fill up the alum dosing solution in tank whenever required. Dosing process will be follow the SOP Calculation | Daily |

| 8 | Poly-Electrolyte Dosing Tank | To fill up the poly electrolyte dosing solution tank whenever required. | Daily |

| 9 | pH Control Unit | To fill up the acid/base whatever required for pH Control | Weekly |

| 10 | Effluent Transfer | To transfer the effluent from collection cum neutralization tank to settling tank | Daily |

| 11 | Effluent Settling Tank | To maintain the minimum 4 Hrs. retention time for water settling tank | Daily |

| To Drain out sludge in sludge drying bed | Weekly | ||

| 12 | Effluent Transfer | To Transfer the settled effluent from settling tank to pressure sand Filter by water transfer pump | Daily |

| 13 | Pressure Sand Filter | To Transfer the effluent from settling tank to pressure sand filter by water transfer pump | Daily |

| To rinse water in pressure sand filter using manual multiport valve operation for 10 minute for 3 times continue. | Daily | ||

| To backwash the water in pressure sand filter using manual multiport valve operation for 10 minute for 3 times continue. | Daily | ||

| 14 | Activated Carbon Filter | To Transfer the effluent from settling tank to Activated carbon filter by water transfer pump | Daily |

| To rinse water in Activated Carbon filter using manual multiport valve operation for 10 minute for 3 times continue. | Daily | ||

| To backwash the water in Activate Carbon filter using manual multiport valve operation for 10 minute for 3 times continue. | Daily | ||

| 15 | Water Evaporation System | To start the water evaporation if gardening area is not enough for treated water ETP | Daily |

| 16 | Treated Water Supply for Gardening | To utilize the activated carbon filter water for gardening purpose | Daily |

|

Operation Specification |

|||

Standard Operation Process for ETP :

Oil & Grease Tank :

- To check the supernatant liquid of oil & grease tank

- If Oil & grease residual found then manually extract by bucket.

- Check the pH of Effluent

Collection cum Neutralization Tank

- Start the Water Transfer pump.

- To Start the agitator for chemical mixing in effluent water.

- If pH is acidic or neutral then Raise the pH of effluent up to 9 by dosing of lime [150 Gram in 2000 Liter]

- After raising the pH upto 9, Start the dosing of alum [200 gram in 2000 Liter ] or maintain the pH 7 by dosing of Alum.

- Once the pH maintain at 7 Start the Cationic polymer dosing [56 gram in 2000 Liter]

- Maintain water mixing at least 20 minute after the dosing of cationic polymer.

- [If color residual found in final treated water then also add the bleaching powder in 5 ppm concentration]

- Stop the water mixing and start the Water Transfer in Settling Tank

Settling Tank

- Maintain the water settling for 6 Hrs.

- Transfer the supernatant water for filtration of Evaporation propose.

- Transfer the settled solid of settling tank to sludge drying bed [Operation is once a week]

Filtration

- Start the water transfer pump of filtration unit.

- Operate the activated carbon filter in Rinse & Back Wash mode for 15 minute.

- Operate the pressure sand filter in Rinse & Back Wash mode for 10 minute.

- Transfer the treated water for gardening propose.

Evaporation.

- Feed the water from settling tank to Evaporator and operate evaporator till water completely evaporated.

Sludge Discharge

- Dried sludge required to supply for GPCB Authorize landfill site

Chemical Requirement in Daily Operation

| Sr. No. | Chemical Detail | Dosing Required for 2000 Liter Effluent | Chemical requirement for 100 liter dosing tank for daily operation of 2000 Liter Effluent Treatment |

| 1 | Lime | 150 Gram /Day | 150 Gram /Day |

| 2 | Alum | 200 Gram / Day | 200 Gram /Day |

| 3 | Cation polymer | 56 Gram /Day | 56 Gram /Day |

| 4 | Bleaching Powder | 37 Gram /Day | 37 Gram /Day |