Erva Healthcare Pvt. Ltd. has installed the compact ETP Plant[Effluent Treatment Plant] for the treatment of capsule and syrup formulated effluent.

Capacity of Effluent Treatment Plant : 1 m3/day

Water Parameter Consideration :

| Inlet Parameter in mg/liter | Outlet Parameter | |

| pH | 6-8 | As per CTO Norms given to you by GPCB[Except TDS] |

| TDS | 1500-2000 | |

| TSS | 200-400 | |

| Color | Blakish | |

| BOD | 190-300 | |

| COD | 450-600 | |

| Oil & Grease | 2 | |

| Sulphate | 99-200 | |

| Chloride | 400-600 | |

| Ammonical Nitrogen | 39-100 | |

| Sodium | 520-600 | |

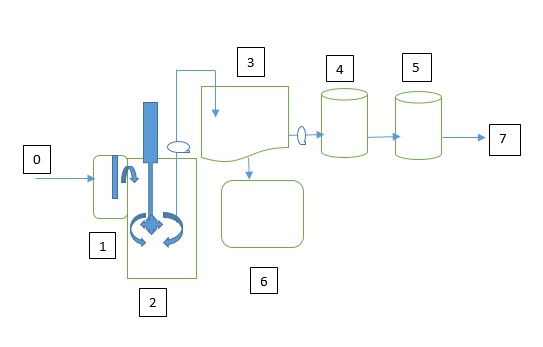

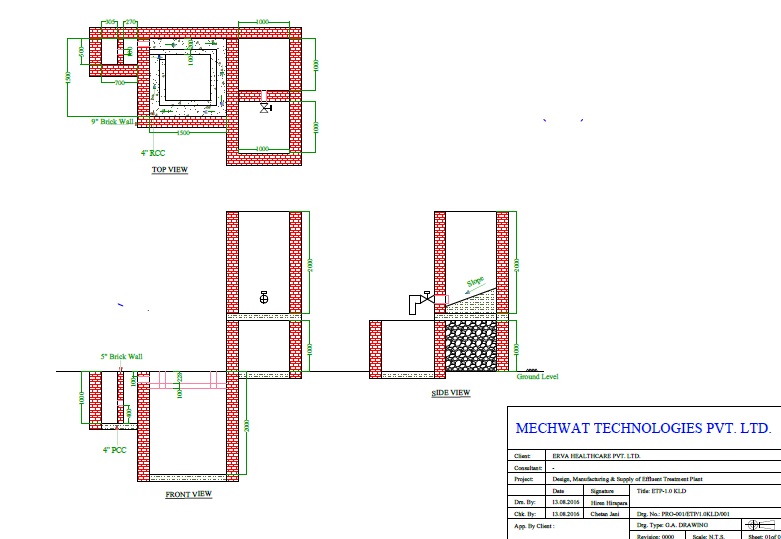

Treatment Process Layout of ETP :

| Sr No. | ETP Process Unit | Size(LxBxH) in M | Capacity (Liter) |

| 0 | Effluent Inlet | – | – |

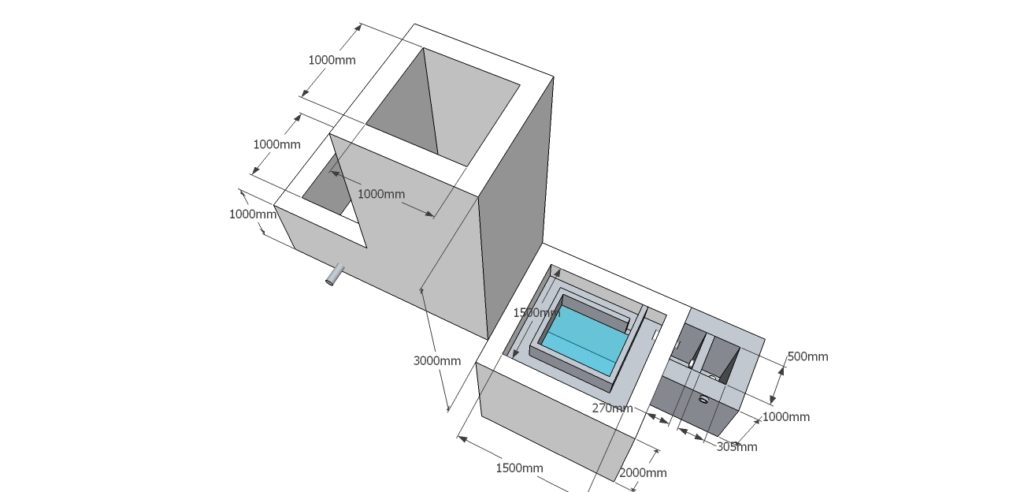

| 1 | Oil & Grease Chamber | 0.5 x 0.5 x 1 | 500 |

| 2 | Collection cum neutralization tank | 1.5 x 1.5 x 2 | 4500 |

| 3 | Settling Tank | 1 x 1x 2 | 2000 |

| 4 | Sludge Drying Bed | 1 x 1 x 2 | 2000 |

| 5 | Pressure Sand Filter | 0.2 x 1.2 | 100 |

| 6 | Activated Carbon Filter | 0.2 x 1.2 | 100 |

| 7 | Water Supply for Gardening Propose | – | – |

| 8 | Water Evaporation System | 1000 liter/hour | 1000 liter/hour |

Treatment Procedure :

Oil & Grease Chamber :

Washing water from Tablet, Ointment unit transfer to Oil & Grease Tank to trap the Oil Content.

Collection Cum Neutralization Tank :

Effluent from oil & grease tank transfer to collection cum neutralization tank by gravity base. Initially pH of effluent water set up at 8.5 by chemical dosing of direct flocculants. Sub sequently pH raise to 10.5-11.5 by lime dosing. Chemical mixing is done by Agitator having 1 HP Gear Motor & SS Impeller Shaft. Initially chemical dosing will help to maximum sludge separation. pH of effluent will be maintain at 7.8 settled for 3 hrs then supernant transfer to settling tank and residual sludge transfer to sludge drying bed through 1 HP mud pump.

Settling Tank :

Treated effluent from collection cum neutralization tank transfer to settling tank by water transfer pump. Flocculated water will be settled to remove the turbidity of water.

Pressure Sand Filter :

Settled water will be transfer to pressure sand filter by water transfer pump. Pressure sand filter remove the suspended solids.

Activated Carbon Filter :

Filtered water from pressure sand filter will be filter out in activated carbon filter to remove the chlorine content and residual.

Water supply for gardening purpose or Evaporation Operation:

Filter out water of carbon filter utilize for gardening purpose or else supply to evaporation purpose.

Standard Operation Process for ETP Operation :

Oil & Grease Tank :

- To check the supernatant liquid of oil & grease tank

- If Oil & grease residual found then manually extract by bucket.

- Check the pH of Effluent

Collection cum Neutralization Tank

- Start the Water Transfer pump in Re-circulation mode.

- If pH is acidic or neutral then Raise the pH of effluent up to 9 by dosing of lime [56 Gram in 750 Liter]

- After raising the pH upto 9, Start the dosing of alum [63 gram in 750 Liter ] or maintain the pH 7 by dosing of Alum.

- Once the pH maintain at 7 Start the Cationic polymer dosing [35 gram in 750 Liter]

- Maintain water recirculation at least 20 minute after the dosing of cationic polymer.

- [If color residual found in final treated water then also add the bleaching powder in 5 ppm concentration]

- Stop the water recirculation and start the Water Transfer in Settling Tank

Settling Tank

- Maintain the water settling for 6 Hrs.

- Transfer the supernatant water for filtration of Evaporation propose.

- Transfer the settled solid of settling tank to sludge drying bed [Operation is once a week]

Filtration

- Start the water transfer pump of filtration unit.

- Operate the activated carbon filter in Rinse & Back Wash mode for 15 minute.

- Operate the pressure sand filter in Rinse & Back Wash mode for 10 minute.

- Transfer the treated water for gardening propose.

Evaporation.

- Feed the water from settling tank to Evaporator and operate evaporator till water completely evaporated.

Sludge Discharge

- Dried sludge required to supply for GPCB Authorize landfill site

Chemical Requirement in Daily Operation

| Sr. No. | Chemical Detail | Dosing Required for 750 Liter Effluent | Chemical requirement for 100 liter dosing tank for daily operation of 750 Liter Effluent Treatment |

| 1 | Lime | 56 Gram /Day | 56 Gram /Day |

| 2 | Alum | 63 Gram / Day | 63 Gram /Day |

| 3 | Cation polymer | 35 Gram /Day | 35 Gram /Day |

| 4 | Bleaching Powder | 37 Gram /Day | 37 Gram /Day |